Advanced FRP, Because No Issue is the Same…

CUSTOM ENGINEERED COMPOSITE REPAIRS AND STRUCTURAL REINFORCEMENT SOLUTIONS

ADVANCED

We Meet API 653 & ASME PCC-2 Industry Standards

What WE Do

FRP REPAIR SOLUTIONS thoroughly diagnoses corrosion and erosion issues to prescribe streamlined custom solutions with the proven Advanced FRP Systems product line!

Carbon fiber repair solutions engineered for stability.

TANK REPAIR

We provide tailored carbon fiber repair services for tank assets in various industries. Regardless of whether the damage resulted from erosion or corrosion, our expert FRP systems team is ready to assist in restoring the reliability of your tanks.

PIPE REPAIRS

Our composite pipe repair solutions are designed to restore and strengthen your pipes. We offer a variety of options, including corrosion prevention, leak mitigation, and the construction of structurally independent composite pipes.

COATINGS

We provide maintenance-free coating solutions with a lifespan of 20 years for a wide range of applications, including those involving water immersion, harsh chemicals, and environments subject to significant wear.

SPECIALTY REPAIRS

Utilize our tailored reinforcement solutions for beams, columns, concrete slabs, and various other structural elements. Our specialized composite repairs are also suitable for underwater applications.

High-Strength, Corrosion-Resistant Composite Tank Repair and Reinforcement

Composite repairs offer a versatile and highly reliable solution for repairs on a wide range of tanks. Carbon fiber patches are available for spot repairs of isolated corrosion or a sectional repair can be done if larger sections are experiencing degradation like the tank floor or floor to wall joint. Full tank reinforcement is an excellent solution for systemic corrosion. It can be engineered either to reinforce the remaining wall thickness or to create a structurally independent composite tank within your existing tank

Composite Pipe Reinforcement for Buried & Above-Ground Systems

Advanced FRP Systems provides durable, maintenance-free carbon fiber repair solutions for industrial piping. Our carbon fiber wrap system can seal leaks, reinforce damaged sections, or fully rebuild pipelines with high-strength, corrosion-resistant composites—often without shutting down operations.

Composite reinforcement offers a fast, cost-effective alternative to pipe replacement. It restores structural integrity, extends service life, eliminates hot work, and improves system reliability.

Before replacing your piping, consult our experts to see if carbon fiber reinforcement is the better solution.

Specialty Coatings for Demanding Environments

At Advanced FRP Systems, we know downtime is costly. Our corrosion-resistant coatings deliver long-term, maintenance-free protection across diverse industrial applications—even in the harshest conditions.

By pairing immersion-grade polymer coatings with expert contractor training and oversight, we ensure over 20 years of service life and unmatched reliability.

Our coatings can be customized for different substrates and corrosive or abrasive environments, including exposure to acids and solvents.

If your current coatings are blistering, delaminating, or showing pinhole corrosion, contact our team for a free failure analysis.

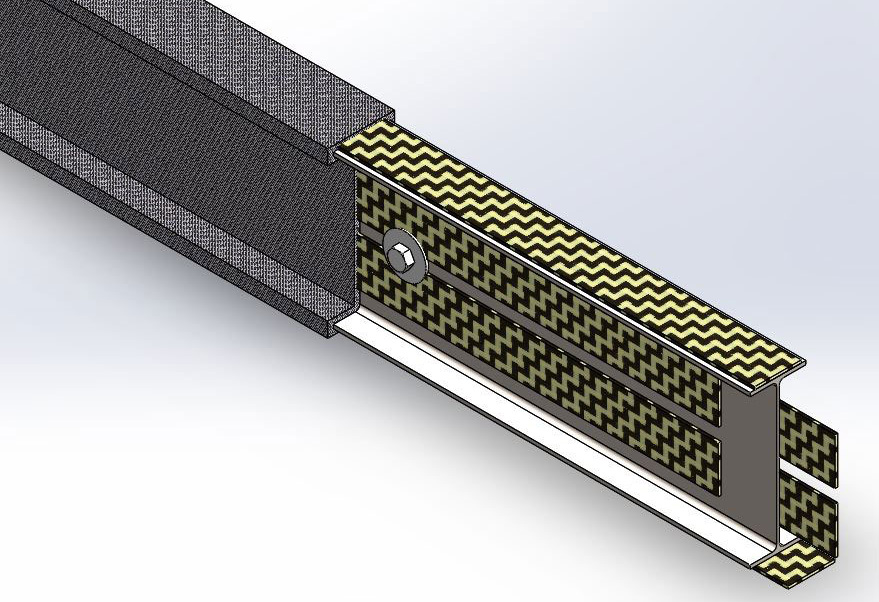

Innovative Concrete Repairs with Composite Technology

Composites offer versatile solutions to repair, reinforce, and protect concrete structures. Our fiber-reinforced polymer systems deliver superior abrasion resistance, underwater application capability, and crack prevention.

Advanced FRP Systems provides customized structural repair solutions—from reinforcing corroded I-beams and rebuilding pillars to restoring offshore and tidal pilings.

We’re not just concrete repair contractors—we’re composite experts. Contact us to find the right solution for your structural or foundation repair needs.

Struggling with Industrial Erosion or Corrosion?

Contact us for a free evaluation.

Power Generation

More Info

Wastewater can be extremely aggressive towards a range of different tank materials, including concrete, steel, and even stainless steel.

Oil & Gas

More Info

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Water & Waste Water

More Info

Wastewater can be extremely aggressive towards a range of different tank materials, including concrete, steel, and even stainless steel.

Mining / Concrete

More Info

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

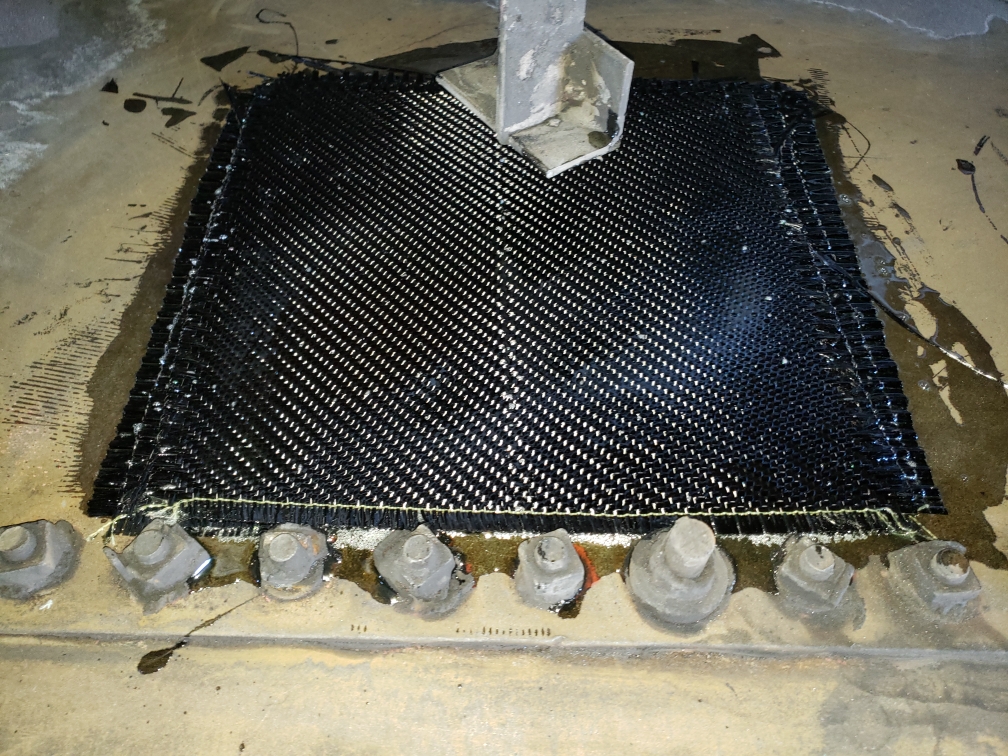

Composite Patch Repair

More Info

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Sewage Storage Tank

Wastewater can be extremely aggressive towards a range of different tank materials, including concrete, steel, and even stainless steel. The content of sewage water not only varies from location to location but often varies from time to time. High hydrogen sulfide levels can be extremely aggressive, especially above the vapor line in storage and process tanks. Elevated chloride levels, as well as low and high pH, are also common immersion conditions in raw sewage. Ensure that your assets are appropriately protected, structurally sound, safe, and effective in the long run by talking with our experts. We can assist with inspections and spot repairs to structurally certified repair options for severely damaged tanks.

Water Treatment Tanks

Demineralization units are critical components of thermal power generation facilities. Often requiring both strong acids and strong bases, these systems are very aggressive towards most coatings, composites, steel, and concrete. We design proven solutions for every part of your water treatment process, including materials that are compatible with immersion in 98% sulfuric acid and neutralization basins. Allow our team to help protect your tanks, pumps, pipes, and secondary containment.

Tank Bottom Repairs

Many hydrocarbon storage tanks, especially crude oil storage tanks, are prone to corrosion on the floor and at the floor to wall joint if any trace water is present. Composite reinforcement solutions will not only prevent further corrosion but will structurally reinforce the floor and floor to wall joint to ensure continued operation of your tank. Our repair solutions are compatible with API 652, and you can use a modified ultrasonic technique to verify the composite integrity and even measure the steel wall thickness right through the composite. Contact our team to discuss a long-term solution for your tank bottoms.

Slurry Tanks

Slurry tanks, especially agitated slurry tanks, are especially erosive and can quickly wear away traditional coatings. Advanced FRP Systems offers a wide range of solutions ranging from abrasion resistant composites to fully structural reinforcement for even the most badly damaged tanks. Many tanks only require repair and reinforcement in specific high-wear areas. Our experts can help you diagnose issues with corrosion and erosion and prescribe the best, customized solution to enhance the life and reliability of your tanks.

A composite patch repair is widely used in the repair of metal and composite parts including pipes, tanks, beams, plates, and pressurized vessels.

A composite patch consists of reinforcing fabric and a resin binder. Composite repairs are performed on damaged steel pipes and tanks, composite laminate structures, fiber-reinforced composites, concrete, and other metallic substrates. The patch is placed over the damaged area after proper surface preparation to ensure adequate adhesion. The patch will prevent leakage, stop further corrosion and provide local strengthening to the patch area.

Small cracks and pinholes within the tank can successfully be repaired using a composite patch repair. To ensure crack growth or propagation does not continue under the composite patch, a crack should always be removed or properly terminated.

A repair patch made of carbon fiber and an immersion grade epoxy is not just a temporary repair; due to its high adhesion strength, outstanding tensile strength, and resistance to many aggressive chemicals, a composite repair patch can provide 20 years of structural health to the repaired tank.

Personal Customer Service

Personal customer service means taking the time to understand a customer’s application, environment, and long-term goals. It means being available to troubleshoot problems, provide technical data, coordinate deliveries, and ensure product compatibility. It’s about offering not just a product, but peace of mind — knowing that someone is looking out for the success of the project.

From plant managers and engineers to maintenance crews and procurement teams, customers value service that feels personal — not generic. A coating may protect steel from corrosion, but personal service protects relationships and reputation.

In an industry driven by performance and precision, personal customer service is what sets a supplier apart. It’s the promise that behind every drum, every spec sheet, and every shipment, there’s a team that truly cares.

Satisfaction Guaranteed

Customer Satisfaction with Advanced FRP Systems: Built on Strength, Delivered with Service

In the world of industrial Fiber Reinforced Polymer (FRP) solutions, performance is everything — but satisfaction goes beyond strength and corrosion resistance. True customer satisfaction is built on how well a company delivers not just the product, but the experience.

FRP is used in some of the toughest environments: chemical plants, offshore platforms, wastewater facilities, and power generation sites. Customers rely on FRP for its durability, low maintenance, and long service life. But they also rely on their FRP provider to be responsive, knowledgeable, and committed to getting every detail right — from design and fabrication to delivery and installation.

Free Consultations

Our free consultation service is designed to help facility owners, engineers, and maintenance teams make informed decisions — with zero pressure and no obligation. Whether you’re dealing with corrosion, chemical exposure, structural damage, or simply planning ahead for long-term asset protection, we’re here to provide clear, expert guidance.

-

Project-specific insight

-

Recommendations on materials and systems

-

Expert evaluation

-

Regulatory and compliance guidance

-

Installation and maintenance planning

Our goal is to give you the confidence to move forward with the right solution — whether it’s high-performance coatings, FRP wraps, or custom-engineered systems. With decades of experience in specialty protective technologies, we understand that every project is unique — and we treat it that way.

Industrial, Municipal, Oil & Gas, Concrete, Aggriculture

Plus many more industry needs.

Contact

Head Office

1616 N. Main St., Pearland, TX 77581

Call Us

(281) 485-9553